29 Sep What Is A Conical Fermenter?

So what is a conical fermenter? And should you be using one when brewing your own beer at home?

A conical fermenter is essentially a cone-shaped fermenter that significantly streamlines the homebrewing process, saving you time, money and storage space. Whether you’ve been brewing for a while and are looking to step up your homebrew game OR you’re just starting your homebrewing hobby, a conical fermenter is easy to use and can help you brew your best tasting beers.

Most brewers begin their homebrewing journey with a carboy or even a humble bucket, but conical fermenters are becoming more popular and more accessible for first time homebrewers or for experienced brewers looking to step up their homebrew game.

At Craft a Brew, our mission is to turn craft beer lovers into craft beer brewers. We design beer brewing kits and fermentation equipment to help homebrewers make the best possible beers at home. Our Catalyst Fermentation System, a conical fermenter introduced in 2016, makes it even easier to make great beer at home without wasting time on unnecessary steps and without all the excess equipment.

We’ll dive into the benefits of conical fermenters and The Catalyst Fermentation System, specifically. We’ll also cover:

-

- the advantages of conicals over traditional fermenters

- how to use a conical fermenter, step-by-step

- the innovative features of The Catalyst Fermentation System

- what to consider when choosing a conical

What is a conical fermenter?

While carboys and buckets have flat bottoms, a conical fermenter is shaped like a cone. Used by commercial breweries – look for them on your next brewery tour – conical fermenters act like giant sediment funnels. During fermentation, spent hops and inactive yeast settle in the cone or in an attached collection container instead of at the bottom of your fermenter.

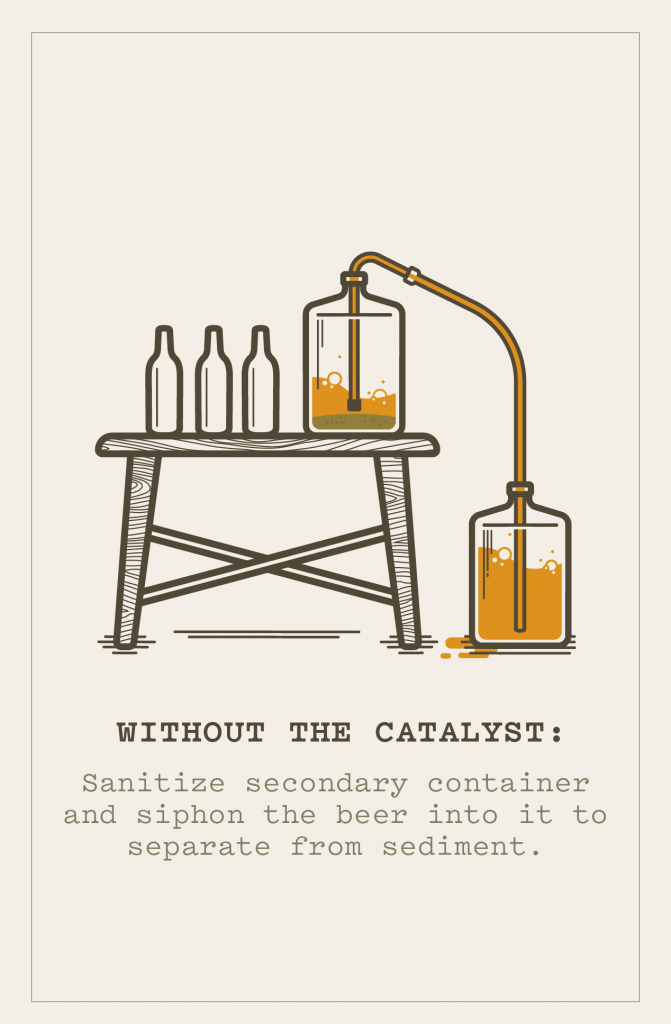

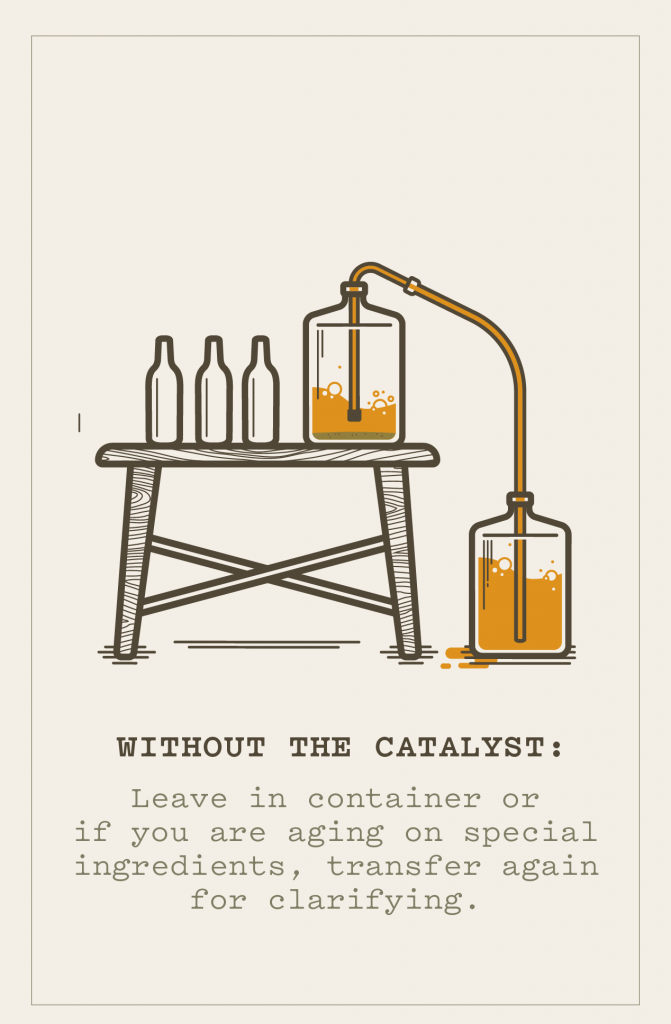

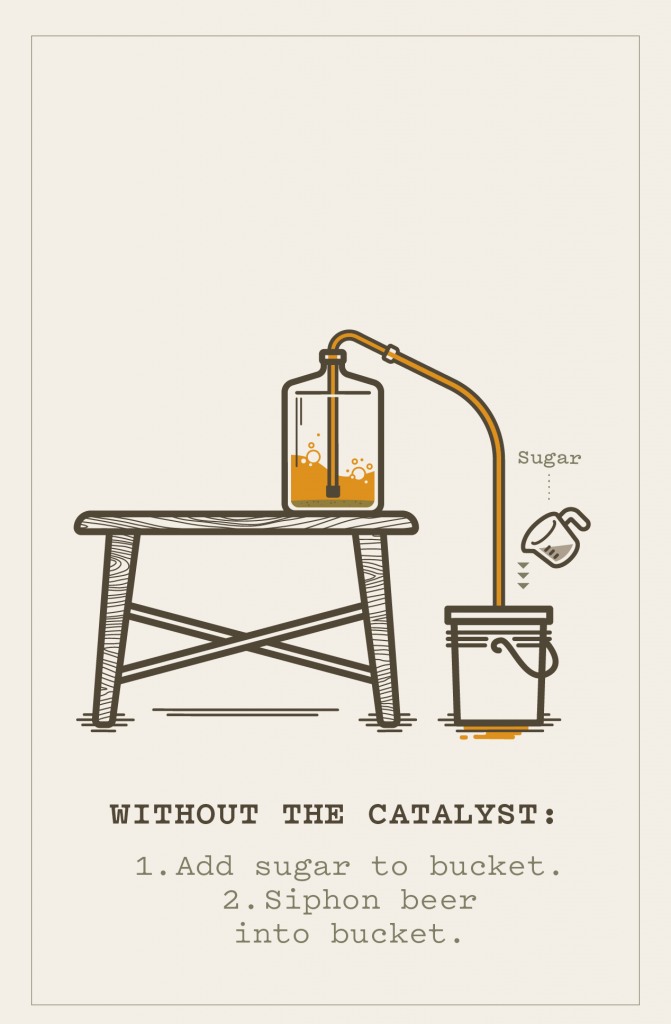

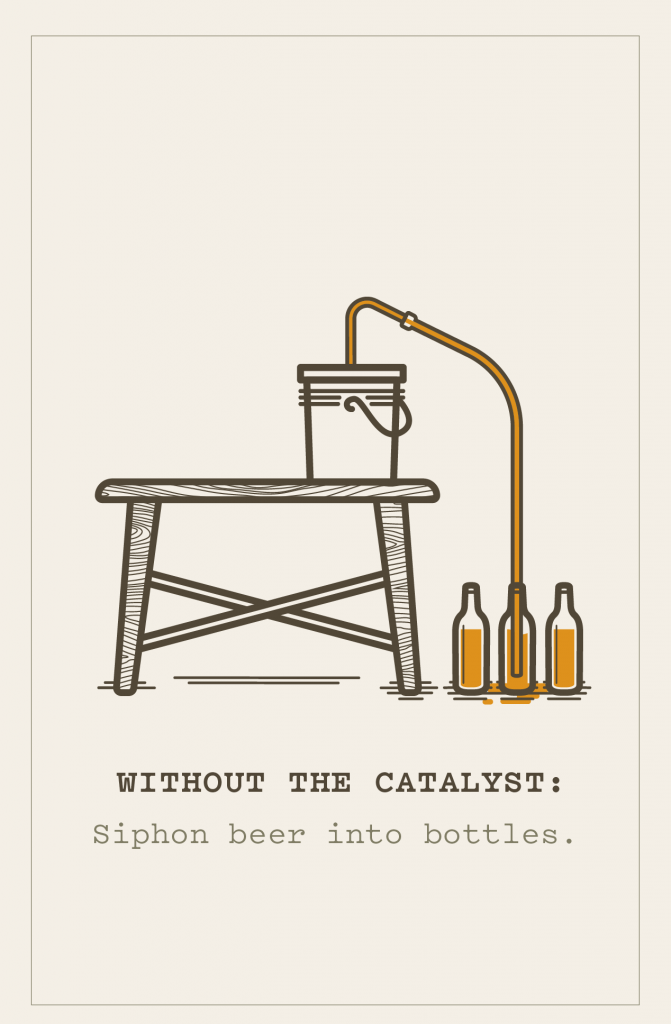

Because beer must be separated from sediment, this traditionally involves sanitizing another fermenter, siphoning beer off the sediment and transferring into the new fermenter. Again, on bottling day, beer must be carefully siphoned from the secondary fermenter into a sanitized bottling bucket and transferred, yet again, into bottles. That’s a LOT of transfers and a lot of time wasted.

Conicals eliminate these tedious, and often messy, transfers by simply removing sediment from the bottom of the fermenter instead.

Advantages of conical fermenters:

Conicals have many advantages over traditional fermenters, which makes one a sound investment in your home brewery. Not only do conical fermenters streamline the entire homebrewing process, but they save you time and effort while eliminating the risks associated with traditional transfers.

Save Time

You already spend hours sanitizing your equipment and brewing, why dedicate more time than necessary during fermentation? With a conical fermenter, there’s less hands on time required during fermentation. Once wort (unfermented beer) is transferred into a conical fermenter you don’t need to touch it until bottling day or kegging.

Primary and secondary fermentation occur in one vessel, so there’s less equipment to sanitize beforehand and less to clean up when your beer is bottled. While sanitation is regarded as the most important part of the homebrewing process, it’s safe to say that it is most homebrewers’ least favorite part of the beer brewing process.

Because many conical fermenters have wide openings, it also makes the time spent cleaning your equipment much easier and quicker! The narrow necks on glass carboys make it difficult to clean and scrub every nook and cranny, but conical fermenters are made of durable materials – like plastic and stainless steel – which makes them less fragile and simpler to clean up.

Save Space

As your homebrewing hobby grows and evolves, you tend to acquire a lot of equipment along the way. Multiple fermenters, auto-siphons, buckets, bottles, kettles and more.

If you don’t have a storage closet to spare or a roomy garage, the traditional homebrewing process and its laundry list of equipment can stop a lot of new brewers in their tracks. It can also annoy an avid homebrewer’s housemates. An all-in-one conical fermenter is an ideal tool for a space-constrained brewer or a brewer looking to simplify their setup.

Save money

Sure, all that extra equipment takes up space, but it also costs money! With a conical homebrew fermenter, you can be a savvy homebrewing minimalist, but you can also save money on brewing ingredients.

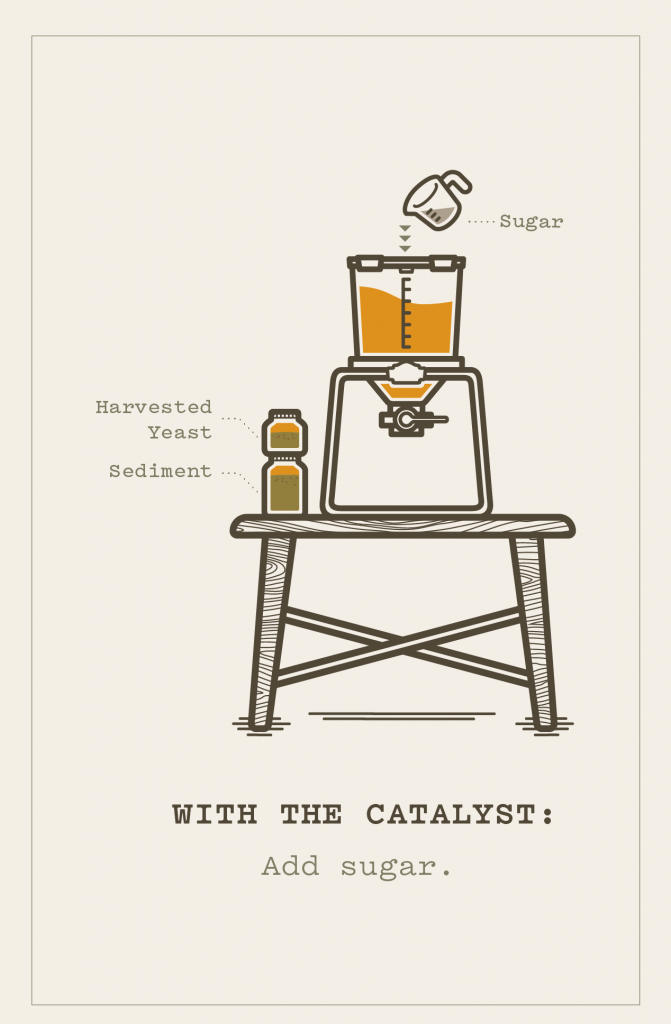

A conical fermenter’s unique functionality – collecting sediment in a removable container – means you can more easily harvest yeast and re-pitch it in future fermentations! The new and exciting experimental yeasts available to homebrewers these days can sometimes cost nearly $20.

If you love a particular yeast strain, a conical fermenter allows you to collect and store it for reuse. More bang for your buck! In fact, yeast can often yield a more active fermentation when reused because it’s already active and alive! So your next batch of homebrew can be improved, especially if you’re brewing a higher gravity (higher alcohol potential) beer.

We’ll show you HOW to collect, harvest & re-pitch yeast with The Catalyst Fermentation System. But you can jump ahead HERE.

Brew Better Beers

Each time you transfer your beer (to a secondary fermenter, to a bottling bucket and again into bottles) you risk oxidation, which can cause unwanted stale or cardboard-like off flavors in your finished beer. Or even worse, you risk contamination.

You spent hours sanitizing & brewing and weeks fermenting. Don’t throw it all away on a transfer gone wrong. With a conical fermenter, wort remains in one vessel until it’s time to bottle, so oxidation is a non-issue and the risk of spoiled beer is immediately reduced.

Conical fermenters don’t just avoid risk, but they can improve your beer too! The conical shape helps improve sediment separation, which results in cleaner, clearer beer.

How to use a conical fermenter:

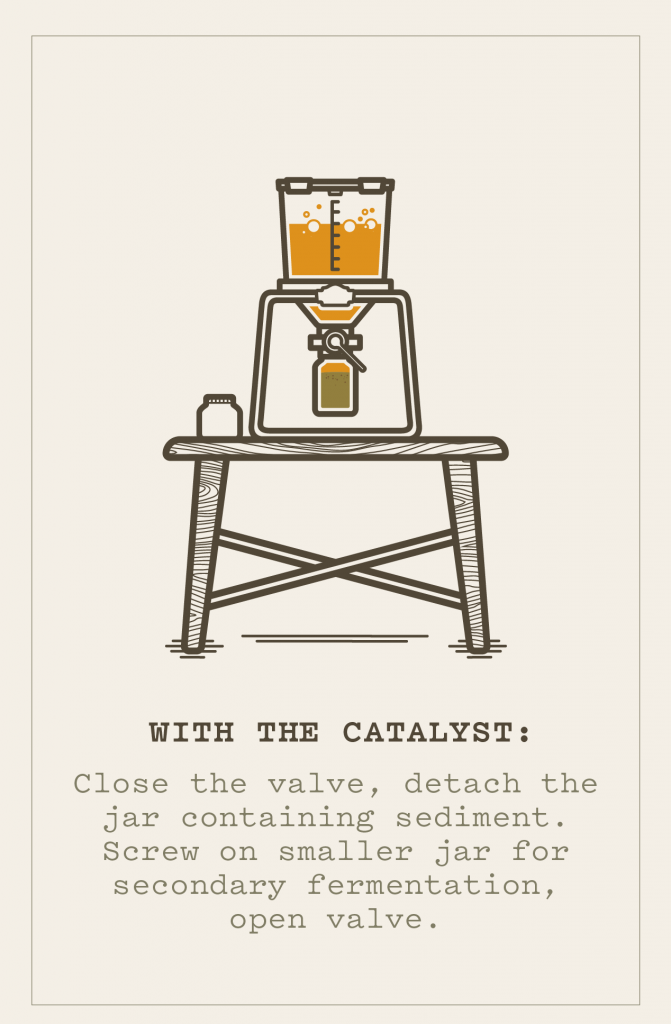

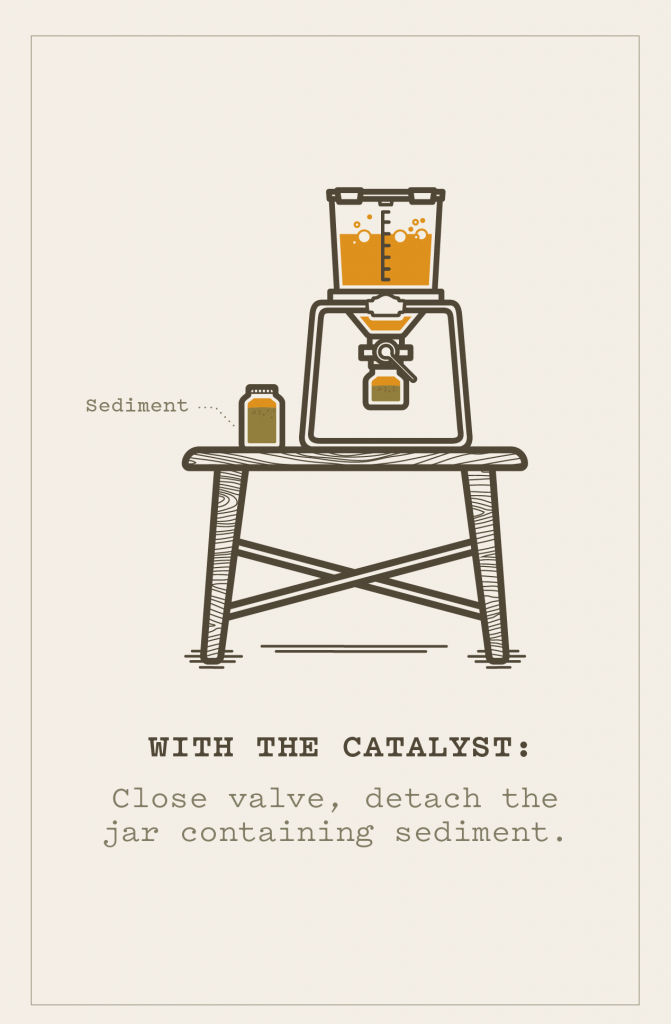

Conical fermenters like The Catalyst Fermentation System simplify all the steps that come after brew day. With a conical, you don’t need to touch your beer until bottling day. Let’s review the fermentation process using a conical fermenter & compare to the process using a carboy.

STEP ONE

Post-primary Fermentation

(after the first 3-10 days of fermentation):

STEP TWO

Secondary Fermentation & Aging

(the next 10-15 days of fermentation):

STEP THREE

Priming your beer:

STEP FOUR

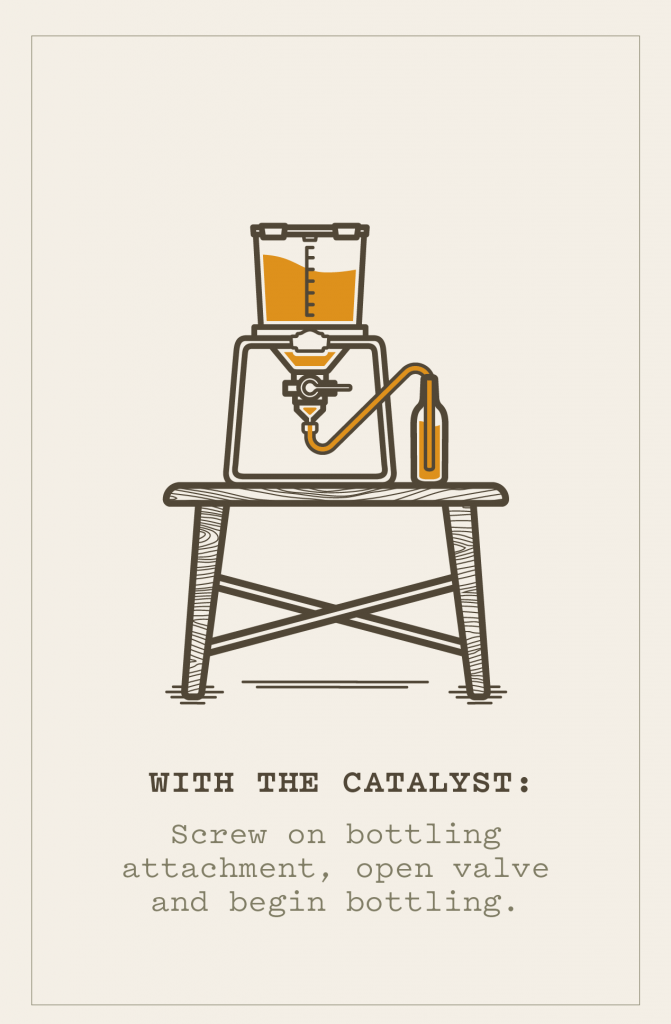

Bottling:

The Catalyst Fermentation System

The Catalyst Fermentation System is no ordinary conical fermenter. It was crowd-funded by more than 1,700 homebrewers and craft beer lovers on Kickstarter in 2016 and has received design awards and recognition from homebrewing publications and homebrewers as some of the top brew gear on the market. We’ve reviewed the basics of conical fermenters and their functionality and advantages, but The Catalyst was designed to improve upon existing conicals with user friendly features and impressive mason jar compatibility.

We’ll discuss the features of the Catalyst and how they can help improve your homebrewed beer and save you even more time while doing it!

The Catalyst was designed with the 5 gallon homebrewer in mind. The 6.5 gallon capacity conical tank is ideal for folks looking to make the jump from 1 gallon brews or for 5 gallon brewers who are ready to ditch their carboys once and for all.

MATERIALS:

The Catalyst’s elegant design and materials were at the forefront of the engineering process. This conical fermenter was designed to be sturdy, functional AND beautiful.

A food-grade, medical-grade material called Tritan polymer was chosen for the tank because of its brilliant clarity and durability. Combining the aesthetics of glass with the benefits of plastic, this material allows brewers to actually watch fermentation as it happens without the fear of broken glass. If you’ve ever had a carboy break, you know the devastating feeling of losing all your precious beer.

Tritan polymer is a state of the art material. It’s nearly indestructible, more scratch-resistant than other plastics and is BPA and PETE free, making it perfectly safe for fermentation.

The polymer material also makes the Catalyst conical fermenter lightweight and easy to assemble. All of its parts are easily disassembled for compact storage and quick clean up. The rugged material also makes the Catalyst quite possibly the easiest conical fermenter to clean. The tank is dishwasher safe!

THE TRUB TRAP:

The Catalyst was also designed with practicality in mind. Many conical fermenters narrow openings will clog with sediment, making it harder to bottle beer or collect yeast. The Catalyst’s generous 3” Trub Trap butterfly valve is the largest on the market – meaning no clogging! The Trub Trap’s size also makes it compatible with ANY wide mouth mason jar.

MASON JAR COMPATIBILITY:

With the Catalyst conical fermenter, homebrewers can screw on any volume mason jar that’s right for the job. Screw on a 16 oz jar for normal sediment removal. Size up to a 24 oz or a 32 oz mason jar if you’re adding a generous dose of dry hops. Size down to an 8 oz mason jar when it’s time to collect clean yeast for future fermentations.

MAKE A MASON JAR YEAST STARTER:

One of the coolest benefits of using The Catalyst conical fermenter is the ability to collect & harvest yeast, then re-pitch it with a mason jar.

Throughout fermentation you’ll notice the sediment that collects in the attached mason jar will start off pretty dark and green (mostly made up of spent hops from brew day and other proteins). Once the first mason jar of sediment is removed and a new mason jar is attached, you’ll notice that a majority of the sediment is milky-colored clean yeast.

This clean yeast can be saved (best used within 2 weeks) to jumpstart your next batch of homebrew. While dry yeast does not require you to make a yeast starter, yeast that’s already been used is now liquid yeast and will require a yeast starter in order for successful fermentation.

TRY A PRE-FERMENTATION TRUB DUMP:

As we discussed, a major benefit of conical fermenters like The Catalyst is improved clarity and cleaner beer from easy sediment separation. Not only is sediment collected and removed during fermentation, but you can do so before adding yeast for a super clean fermentation. This is accomplished through a pre-fermentation trub dump.

A lot of sediment is created on brew day from hop pellets, proteins from the grains and any other adjuncts you brew with like fruit or spices. It can be difficult to remove all of this with a filter before transferring to your fermenter. You don’t have to sweat it with The Catalyst.

Pour all of your wort into the conical fermenter, kettle sludge and all. Before you add yeast, allow this trub and sediment to gradually settle in the attached mason jar. You can let your wort sit for a few hours or overnight. Once your jar is full, close the butterfly valve, remove the mason jar & dump it. Reattach a mason jar (empty or filed with your harvested yeast starter) and begin fermentation.

A pre-fermentation trub dump is not necessary, but is a simple way to remove a lot of sediment to ensure a cleaner fermentation and to eliminate the need for filtering your beer. Just another time-saving step that makes conical fermenters a great choice for every homebrewer!

What to consider when choosing a conical fermenter:

There are more conical fermenter choices for homebrewers now than ever. Whether you’re looking to spend $100 or several hundred or you’re looking to brew 3 gallons, 5 gallons or 20, there is a conical fermenter for you.

A few things to consider when choosing a conical:

SIZE:

Conical fermenters tend to be designed for 5 gallon volumes and larger. There are very few 1 gallon conicals on the market because they tend to produce much less sediment than larger batches of beer.

Conical fermenters are often elevated on a stand or legs to allow access to the underside of the fermenter for sediment removal. Depending on the area in your home where you plan to ferment, you should consider the height and overall size of the fermenter to make sure you choose one that fits your space.

The Catalyst Fermentation System was designed to be shorter than other conicals so that it could fit in smaller spaces (closets, cabinets or shelves) and fit into chest freezers & refrigerators for fermentation temperature control.

MATERIAL:

Most conical fermenters are made of stainless steel or plastic. Be sure to research the plastic materials to ensure that they won’t leach into your beer. The Catalyst uses food-grade, medical-grade polymer that is BPA & PETE free, making it perfectly safe for homebrewing.

The Catalyst can be disassembled, unlike some other fermenters, which makes it easier to clean up and store.

Another factor to consider when choosing a material is visibility. The Catalyst’s clear tank makes it possible to get a front row seat to fermentation. Like clear carboys, you can watch yeast slurry and dance around the fermenter and monitor fermentation activity.

More importantly, you can see precisely how much sediment is collecting in the fermenter and in the attached mason jars, which can prevent premature sediment removal and reduce waste. Stainless steel fermenters don’t let you sneak a peek during fermentation and make it more difficult to check on sediment levels.

PRICE:

Your fermenter is where your beer becomes beer, so it’s certainly an investment. Though, if you’re just beginning your homebrewing hobby, you may not want to jump in headfirst and spend several hundred dollars. But remember, a conical fermenter streamlines your entire setup, making other accessories and equipment unnecessary.

Over time a conical fermenter saves you time (which is priceless) and money on extra equipment, spoiled beer and yeast!